|

Hard at Work in a Button FactoryThese three Muscatine ladies all experienced work in a button factory.

They also are related to one another. Becky Swayze is Debby Kerr's mother-in-law and Ellen Figgins is her aunt.

Debby Kerr, Becky Swayze & Ellen Figgins (Photo by Kari) I spent a delightful lunch hour with these three happy ladies at the Muscatine Pearl Button Restaurant getting to know them and talking about "the good old days" when they worked at the Muscatine button factories.

Becky has two children. Debby says that her mother-in-law is a great cook and taught her how to make homemade noodles. Becky, a hard worker all her life, claims she "learned to work" at the button factories. She also has been, for many years, a frequent volunteer at the Seventh Day Adventist Community Center which gives out free clothing, furniture, and food.

I feel connected with Ellen, Debby's aunt, because for several years we lived next door neighbor to her son and family. She also has raised her sister's two kids. Ellen still cans interesting things like carp, which turns out like elegant salmon. Debby says that she is a wonderful cook and baker, even making and decorating wedding cakes plus is a capable seamstress, sometimes making her first husband's suits in the past. She also owned and operated a ceramics shop. At present she is an avid quilter. Debby has one son and a step-daughter whom she considers as her own. Our mutual interest in jewelry and local Mississippi River pearls led to the making of this page about work in a button factory. Her husband has worked as a diver doing clam surveys and as a local riverboat pilot on the Mississippi River. Working in a Muscatine Button Factory

Hi, we're the button factory girls! We used to work in a button factory here in Muscatine, Iowa. We especially enjoyed working at the Ronda Button Factory which was located close to the Mississippi River. So, what what it like to work in a button factory? Glad you asked. Let us tell you all about it. Ellen: First we mounted the many stairs in the brick Schmarje building next to the Mississippi River in Muscatine, Iowa, to get up to the factory floor. Here automatic button making machines were lined up. we had our special machine that we worked at every day. After greeting the other gals and guys who also spent their days cutting out button blanks from shells, we nestled down at our posts, but not until we gathered a load of freshwater pearl mussels to bring back to our stations.  Muscatine High Bridge 1969 Photo taken by Lonnie Hillman (Photo used with permission.) Becky: Each of us took our washtub over to the mussel holding tank where mussel shells were kept in water. We scooped up mussel load after mussel load with our two hands and placed them in a washtub which was also filled with water. The water was often very cold for the work in a button factory. In winter they had good heat but you notice the cold more. In the summer, you thank heaven for the cold water. We'd come home at night and our hands would be white with cold.

Ellen: The washtub usually was too heavy to carry, so instead of carrying it back to our machines, we would scoot it along the floor with our feet or drag it until it reached our button cutting place. Were the shells clean? Well....let's just say we didn't see any roaches, like some remember seeing. We wouldn't have stayed at work in a button factory if we saw them. Becky: I was at work in a button factory in my late twenties to thirties and worked there when I was both single and married. Ellen: I was sixteen when I went to work in the button factory. You had to be sixteen to work there and worked in them until about age 25. Becky: For both of us work in the button factory was the night shift which was 3 PM to 11 PM. Ellen: We wanted to work as fast as possible. Work in a button factory was piece-work and if you didn't cut your quota you didn't make as much money. And if we cut over our daily quota we would get extra pay...so we worked like the devil to get the quota out! We probably made about $1.70 per hour. Ellen: The clams were of all sorts, like pocketbooks which were ridged, like little mountains on 'em and other kinds. Becky: We cut "shinies" out of the hinge part of the clam. Buttons cut from that part looked like a pearl....a rainbow pearl look. They just glistened! The "shinies" were kept separate...and were the higher quality buttons. To cut the "shinies" you'd put the shell over the plug right next to the saw and the saw would come down. If our work in the button factory was to cut "shinies" then that was the only one you cut and then the shell went on to someone else to cut more buttons around the sides. Ellen: The "shinies" never got over the size of a line 20 button and were considered premium buttons. Becky: That part, where the "shinies" were cut from was also the part of the shell that people would cut designs out of. When all the buttons blanks were cut out....then people still made use of the remainder of the shell for artistic designs.

Muscatine River Front (Photo used with permission.)

Ellen: My mother made me a set of doves...and I never did get those drilled for earrings. I don't remember which one of the girls I gave them to. My mother carved them herself on a demery wheel. Those wheels can eat your fingers up too. Ellen: There were little bitty shells that I cut baby buttons from. I could hardly get the shell on the bit. Becky: I cut a baby button blank out of a tiny shell and smoothed it with a nail file and polished with nail polish and wore that on my neck for a long time. Ellen: Every day during work in a button factory we cut the same size buttons blanks from the shells. Our three fingered gloves for work in a button factory were intended to protect our hand from the sharp edges of the mussels, but well....you know how that goes...The shells are sharp and they spin if you don't hold them real tight and they eat the gloves up. Usually they'll catch at least once if not twice. Becky: Here, see my scars from those sharp edges that cut into my fingers. The shells are just as sharp as razors. Becky: I would hold a mussel shell with the outside part up in my hand...the one with a glove on and place it under the button cutting machine. These machines would spin down with a cutter that went around and around until a coin shaped button blank was cut out of the shell. I had to hold on tight to keep the shell in place while it was being cut. Becky: Sometimes, during work in a button factory the shell would slip out of my hand. Here, I'll roll up my sleeve. See this long scar on my arm? I got that one day when a shell flew out of the machine and whipped up my arm. My boss took me to the Bellevue hospital that day. for a tetanus shot. So for two or three days I didn't work after that.

Ellen: The Bellevue hospital is a private home now, but then it was the city hospital. Becky: Did I quit my work in a button factory? No. These people were great to work for. I think that is why we workers stayed so long...they were just the nicest employers. They weren't hard on us. They let us do pretty much what we wanted...I suppose we got pretty wild sometimes. I tried working at another button factory once, but only stayed a few days. I just didn't like my job there or the atmosphere, so I went back to the Ronda Company. Claus had the button factory and Ron had downstairs machine shop. Ellen: Old Claus was my cousin's father. His daughter married my cousin. Becky: Claus would sit down during my work in a button factory and watch me cutting button blanks. I never did figure out if he was trying to show me something or what. He was pretty nice. Ellen: No...he just liked to cut buttons I think, he used to do that to everybody. Becky: Other work in a button factory that I did was to drill holes in the shanks...that was with a side drill. Ellen: I carded buttons and shanks and even carded buttons at home when I was a little girl. My mother and father carded buttons during the depression there was no other way to make a living. We got 2¢ a gross...that's 144 cards. They were "Blue Bird" and "Lucky.." something, they had a woman on, maybe "Lucky Lady." Some people think we got 2¢ a card....but oh, no, not during the depression honey!

Ellen: You had the cards, and little silvers...little pieces of tin foil, you had to lick them and put on the card and the buttons were sewed on over that with strong thread. The silvers made the buttons look pretty when they reflected on the foil.

Becky: To keep down the fine dust which comes from such an operation during work in a button factory, there was a flow of water coming down the machine at all times. So my hands were often under the running water during work in a button factory. Ohhhh....that water was often cold too, just like the water which the shells were soaking in. But that was better than breathing all that fine dust. It also kept the shells softer to make them easier to cut. Ellen: So are my hands arthritic now from all the cold water running on them? Yes, I would say so, but I loved the work in a button factory. Those were depression days. I was glad for a job. Debby: It's a shame we don't have more photographs of the work in a button factory, but no one ever thought of taking a camera to work...just like today nobody thinks of taking photos of them working. By a stroke of luck there is this rare photo of Becky at her button cutting machine while at work in a button factory.

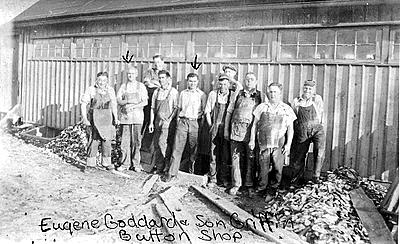

Becky Swayze--Work at a Button Factory, 1960 (Photo used with permission.) Ellen: I have photos of the parties up at Ronda's. Everyone would cook something and they'd have a party like at Christmas time, but they aren't photos of them working. Work in a button factory wasn't all work! Becky: For dinner we'd either bring our lunch or go to a little restaurant up the street about a block away...can't remember the name of it. My aunt, Pearl, had a little store up the street. We'd go up there and get apples, but she didn't want to stay open until midnight every night. Becky: The majority of us were ladies, but there were also men who would work in a button factory. Ellen: It wasn't hard work to learn to work in a button factory. But if you didn't get it the first night, you'd better go home. I think we made more there than we did anywhere else. My mother had work in a button factory called Hawkeye and I worked there for a little while and I didn't like it. I was there for a couple of weeks. I had to grind big shells there and I didn't like grinding. I cut my fingers all the time. My hands are important to me. Becky: I worked for a short while too at another factory, but it didn't last long. Ellen; I was "flutter bug" and did every job with buttons. I also worked on a machine like the hole drilling machine on display at the Pearl Button Factory. My job was too keep buttons on the plugs so they could be drilled. I had to work fast, but never got my fingers caught. I like my fingers!  Becky & Ellen by Button Drilling Machine (Photo by Kari) Ellen: I always wanted to cut buttons because my dad cut buttons. He did not work in a button factory, but he worked for himself in his garage with a machine he purchased. I used to stand and watch him cut buttons when I was little and they had a rhythm that they went to all the time as they cut their buttons. Their machines were singular. They would go to a button factory and buy the clams and take 'em home and cut the buttons out of them and then they'd take the buttons back and get so much for them. During the depression it was his full time job. He would cut buttons every day from 7 to 5. He did not have a name for his business....just "Button Shops in their Garages!"  Dollman & Hoffman Button Company, 1923-1927 300 Jefferson Street, Muscatine, Iowa (Photo used with permission.) Eugene Goddard, Becky's grandfather, is second from the left. Griffith Goddard, Eugene's son, is fifth from the left, Becky's Uncle. Debby: Lots of people had button shops in their garages instead of work in a button factory. They would usually have name for their business if they hired employees and had others working for them. Just about every block had a shed or garage where they cut buttons and sorted. It was real popular. Ellen: My dad only cut one size of button blanks, just like those who work in a button factory. If there was room for extras to be cut out of the shell, someone else took the shells and did it. You would walk into one of those sheds where they were cutting buttons and usually they would have 3 or 4 men, and you'd stand there and watch them and each one had the rhythm just like they were dancing...."The Button Dance," I guess you could call it. Ellen: The rhythm happened when they put the shell in and then they reached over and took this and brought it this way into the saw and into the shell and they would take it back and remove the shell. It was just a rhythm. I especially remember that. Debby: I think I would remember that if I were a child. I'd remember the dancing part. Ellen: My dad clammed too, but they wouldn't allow the women out on the clamming boats. We would stay home and cook off the clams. They went into big barrels of hot water outside and when the clams went into it they would open up and then we took out the clams. We used to eat them. It was the depression. Food was food. They were no different from clams we eat now. Ellen: We would find pearls sometimes, but they weren't good pearls. The hot water didn't ruin the pearls because it they were only in the heated water a short time to open the mussels. Debby: They were odd shaped. Ellen: Well, if they were odd shaped and you could have them peeled. My uncle Walter found a beautiful gray pearl and he had it made into ring for his wife. Pauline Brady's got it. It was about the size of a pea after it was peeled. It had to be peeled. Jewelers peeled them. If an untrained person peeled them, they could ruin them. Only a pearl jeweler knew how to peel them. Becky: I sold some pearls that I found that were attached to the shells I was cutting when at work in a button factory. If I was cutting the shell it was okay for me to take any pearls I found. It was pretty lucky to find one and everybody knew it when you did. Ellen: They're called Mississippi River pearls.  Mississippi River Front in Muscatine (Photo used with permission.) Debby: They're really rare too and hard to find now.

Debby: I had a Mississippi River pearl ring made. The pearl was not round, not perfectly round, but it was close, so it was a very nice ring. I had two pearls, one almost tear shaped that is now a necklace. I don't think it was ever peeled, because it is still odd shaped. It's not round, not perfectly round, but it's close, so it's a very nice ring. Ellen: The cutters at home had motors and the shells were kept in water there too. Water softened the shells and also kept the dust down. The holes weren't drilled at home but back at the main factories on special machines. Becky: At Schmarje's (Ronda Button Factory) the button drills worked with air compressors. When you pushed the petal, it brought the chuck up and the saw down. We stopped the work in a button factory when the air compressor broke down and they never started it up again. Ellen: They started shipping everything to Japan and it was hard to get shells so work in a button factory drastically slowed down. Some were coming from the Arkansas River and when that stopped they just gave it up.

Debby: My husband's family donated a button machine to the Muscatine Art Center and other collector's items like specialty buttons. Becky: Once I was cutting size 17 blanks and a fellow worker looked in my bucket and said, "Nobody ever cut that many buttons in a week!" Becky: I learned to work in a button factory! Between three places... Schmarje's and Pearl Works there on east third, I worked fifteen years cutting buttons.

Becky: After the work in a button factory ended we went other places to work, but they were never as interesting as working on the shells. During work at the button factory we could get up and walk around. Debby: Everyone had work at a button factory. That's what we did. I was younger, but I worked at Muscatine Pearl Works for one year carding buttons. Button carding machines required lots of concentration which was difficult because it was so boring to work in a button factory even if they played music. It was also very hot to work in a button factory, with no air conditioner. I was younger than most of the employees and because my fingers were nimble, I was given the tiny white plastic buttons to card. Flat white buttons on white cards...all day long, one after the other. I lined up the buttons and brought the pneumatic stapler arm down with air and stapled each button separately. There was a quota which the floor supervisor counted. She reminded us if we were below minimum. The building is still there in South Muscatine, but the factory closed in 1985. Ellen: Years ago, everybody had to work, especially during the war! The men were in the service, over seas, you got $50 a month from that. But nobody was disappointed when the work in a button factory stopped. Other opportunities came around.

Kari's note: See photos of the old Ronda Button Factory which closed in the 1950's and is a time capsule....the gloves are still on the tables. It would make a great Muscatine museum and popular tourist attraction. I love hearing people's stories about work at a button factory. Also, I love seeing your Muscatine Mississippi River pearl jewelry and would be happy to add photos of them here on www.KariPearls.com. Do you have a Muscatine work in a button factory story to tell? You may use the handy contact form below to tell your work in a button factory story or to contact me.

Have You Had An Experience With Muscatine Buttons?You are invited to share your experiences working with Muscatine buttons, whether it was in a factory, gathering shells or just watching. We love hearing your stories about the local button industry....and all the details. Please tell your story and share a photo. What Other Visitors Have SaidClick below to see contributions from other visitors to this page...

A VERY YOUNG DISAPPOINTMENT STORY

Lake City Button Factory

My Grama's Story

Muscatine Pearl Button Memories

Pearl Button Memories Not rated yet

|